BOILER DESIGN

The boiler is the heart of a steam power plant. It is a device for converting the chemical energy contained in fuel to heat energy in the steam. There is a burner which mixes air and fuel for combustion, a metal surface for transferring heat from the hot gases to the water, and water for conversion into steam.

Steam bubbles are formed on the inside surface of the boiler, released from this surface and passed upward through the water. Because the steam bubbles are released from the boiling surface at the bottom of the boiler and the voids are replenished by water from the upper colder portion, we have a natural circulation boiler. That is no mechanical means are used to cause the steam to pass upward and the water to pass downward.

Every boiler must convert the chemical energy contained in the fuel to heat energy in steam. In order to do this the boiler must cool the hot combustion gases to the minimum possible temperature to recover as much of the heat energy in the gases as possible, and the circulating steam and water must cool the metal tubing in the boiler effectively.

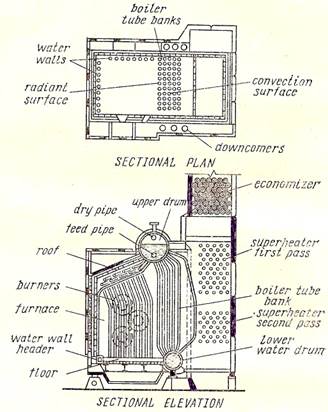

Figure shows a modern water-tube boiler. Burners are located in front of the furnace. The furnace is like a large box enclosed on three sides, the roof, and the floor by panels of steel tubing. All of the tubes (furnace wall floor, and roof tubes) are connected through a system of headers and piping to both the upper and lower drums. The fourth side of the furnace is enclosed by a row of screen tubes which are widely spaced. The first row is backed by several more rows of tubing also spaced widely. This section of the boiler is called the boiler tube bank. All of these tubes are also connected to the upper and lower drums.

All of the tubing surrounding the furnace is called radiant heat transfer surface because flames emit radiant heat energy and these tubes absorb the radiated energy.

The tubes behind the first row in the boiler tube bank are not exposed to radiant energy from the flame. These tubes are considered convection heat transfer surface because they absorb heat from the hot gases by means of convection heat transfer.

The gases that pass from the furnace and through the boiler tube bank are still very hot. In order to obtain more of the thermal energy from the gases, additional convection-' heat transfer surface is provided. Superheater tubing is used to further cool the gases. No boiling takes place in these tubes; they are fed with saturated steam from the top of the upper boiler drum and as the gases are cooled the steam is superheated. The figure shows that the superheater is divided into two sections.

After the superheater an economizer is provided to cool the gases further. No boiling occurs in the economizer. The economizer receives feed water at one end, and the heated water at the other end is fed directly to the boiler feed pipe located in the upper drum.

The figure does not show a gas air heater. Air heaters are used to heat combustion air and to recover more of the heat energy from the exhaust gases before they are sent to the stack.

WORDS TO BE KNOWN

steam power plant - паросиловая установка

steam - пap

burner – форсунка

combustion – горение

surface – поверхность

bubbles - пузырьки

to release высвобождать

voids - пустоты

to replenish - пополнять

to recover - восстанавливать, получать обратно

furnace - топка

enclosed - закрытый

roof - подволок (топки)

header - коллектор

row - ряд

screen экран

Notes

radiant – радиационный

to emit – излучать

to expose – открывать

superheater - пароперегреватель

saturated – насыщенный

directly - непосредственно

air heater – воздухоподогреватель

exhaust - выход, выхлоп

stack - дымовая труба

natural circulation boiler - котел с естественной циркуляцией

hot combustion gases - горячие продукты сгорания

row of screen tubes - ряд экранных трубок

water-tube boiler - водотрубный котел

boiler tube bank - пучок котельных трубок

radiant heat transfer surface - радиационная теплопередающая поверхность

convection heat transfer surface - конвективная теплопередающая поверхность

superheated steam - перегретый nap

exhaust gases - уходящие газы

upper boiler drum – верхний котельный барабан (пароводяной)

gas air heater – газовый воздухоподогреватель

rows of tubing – ряды трубок

REFPLANT

CYCLE OF OPERATION

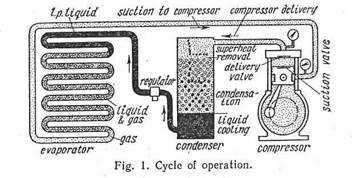

A simple refrigerator circuit is illustrated diagrammatically in Fig. 1.

The evaporator coils may consist of grids on the walls and ceiling of the chamber to be cooled or may be in the form of an air cooling battery placed behind a screen or, again, in the form of coils in a vessel containing brine, water or other fluid.

The evaporator itself is first cooled by the refrigerant and then it in turn cools the surrounding air or other medium. This absorption of heat by the evaporator causes the refrigerant to evaporate (change from a liquid to gas) until finally at the end of the circuit only dry gas at the pressure shown on the gauge should remain to pass into the compressor.

If the regulator is passing an excess of refrigerant, then the gas entering the compressor will still contain some liquid which will cause the crankcase to become cold or frosted, with a cold delivery pipe. If the regulator is insufficiently open, all the liquid will have evaporated before reaching the end of the circuit with the result that only part of the evaporator coil can do useful work.

A regulator which is properly adjusted only passes liquid refrigerant at the rate at which it is formed in the condenser, and preserves the right proportion of the total charge in the condenser and in the evaporator.

In the compressor the gas is recompressed to the pressure necessary for condensation, after which it passes into the condenser.

In the condenser the heat of evaporation and compression is extracted by the condenser cooling medium (water), resulting in the gas again becoming a liquid.

The pressure in the condenser will correspond to the temperature of condensation and this relationship is shown on the gauge.

A receiver or liquid reservoir is supplied with some plants to act as a storage vessel for surplus refrigerant resulting from variations in the demand on the plant.

After leaving the condenser the liquid refrigerant passes back to the regulator to repeat the whole cycle of operation.

Words to be Learnt

simple – простой; medium – среда; absorption – поглощение; coil -змеевик, кольцо; to cause - быть причиной, заставлять; chamber камера; screen – экран; to evaporate – испарять, испаряться; vessel -емкость; brine – рассол; finally – наконец; fluid – жидкость; dry -сухой; to surround – окружать; gauge – прибор, измеритель; to remain – оставаться; to pass – пропускать; excess – избыток; to preserve – сохранять; crankcase - картер (компрессора); charge – заряд; frosted - заиндевевший; покрытый инеем; to extract – отбирать;to correspond to – соответствовать; delivery pipe - нагнетающий, to supply - снабжать, подавать, подающий патрубок; plant – установка; insufficiently – недостаточно; to act as - действовать в качестве; to reach – достигать; storage - хранилище, склад; useful – полезный; surplus - лишний, избыточный; properly - должным образом; demand – потребность

to adjust - регулировать, настраивать

LABORATORY WORK