|

1.4Insulation check

| The insulation check and resistance measurement list is not included in this FCM. It is documented separately |

1.5Remote Serial link: voltage check

|

| RSL | Measurement points | RSL Voltage | ||

| Voltage | Reference point | |||

| Car Link (P101C) | P22M:7 | P22M | P22M:8 (HL2) | 27 - 36 VDC |

| Hall Link (P1H) | Terminal 30 | TB2 | P22M:8 (HL2) | 27 - 36 VDC |

1.6Remote Serial link for inspection mode

Reconnect the car link (P101C: COP is not installed) to operate in INS mode

|

1.7Battery check (E/I-panel)

|

| LED | Description | Status | ||||||||

| BAT-CHARGE | Fast charging/ Pre-charge qualification | l / ☼ | |||||||||

| MAINTENANCE | Maintenance charging | l | |||||||||

| FAULT | Pre-charge qualification/ Fast charging/ Maintenance charging | m | |||||||||

| BAT-MODE | SPBC_II supplied from controller | m |

| Note: The battery is charged by the SPBC_II. When the power of the system is switched off, the battery will be discharged due to the ongoing power demand from the SPBC_II. When switching off the unit for a longer period of time (> 6h), please disconnect the battery and don't forget to re-connect afterwards! |

1.8CAN and SVT communication check (E/I-panel: SPBC_II)

| LED | Description | Status | ||||||||

| CAN_OK | CAN Bus available | ☼ | |||||||||

| SPB_OK | Software proper running, self test passed | ☼ |

|

1.9TCBC check (E/I- panel: SPBC_II)

·Check the proper inputs (use the LED indications located on SPBC_II)

| LED | Description | Status | ||||||||

| GRP/J | Error in the line voltage supply | m | |||||||||

| NOR/DIAG | Normal mode | m | |||||||||

| INS | Inspection mode | l | |||||||||

| ES | Emergency Stop | m | |||||||||

| DW | Hoistway doors closed | l | |||||||||

| DFC | Doors fully closed | l | |||||||||

| DOL | Door Open Limit | l/m | |||||||||

| DOB | Door Open Button | l/m |

| Note: If after switching on the main switch, the status of the LED indication differs from the status listed in the table, check the circuits of the corresponding LED's. |

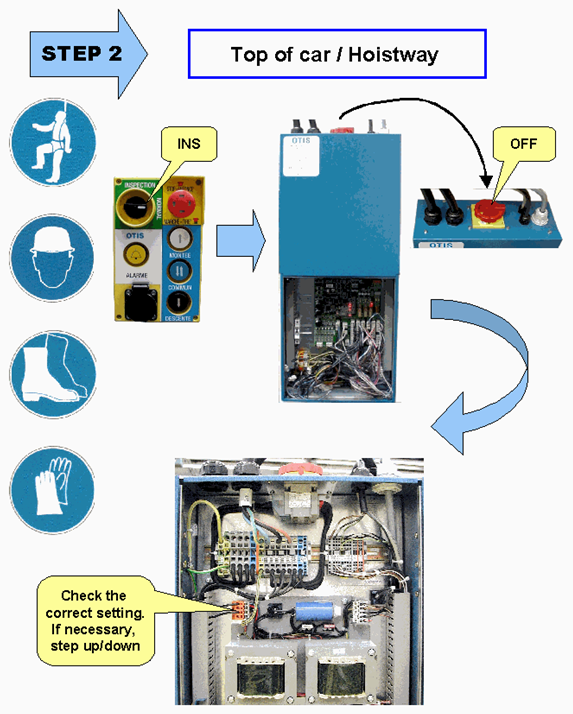

2Starting up in inspection

2.1Parameter Setup (E/I- panel)

|

| Control Parameters | <3> <5> <2> <GOON> | |

| SpC FNr 1) | = | |

| SpC FN0 1) | = |

1) Necessary to avoid roll back without load weighing

| Profile parameters | <3> <2> <GO ON> | |

| INS SPE | = | |

2.2Encoder Adjustment (E/I- panel: SPBC_II)

|

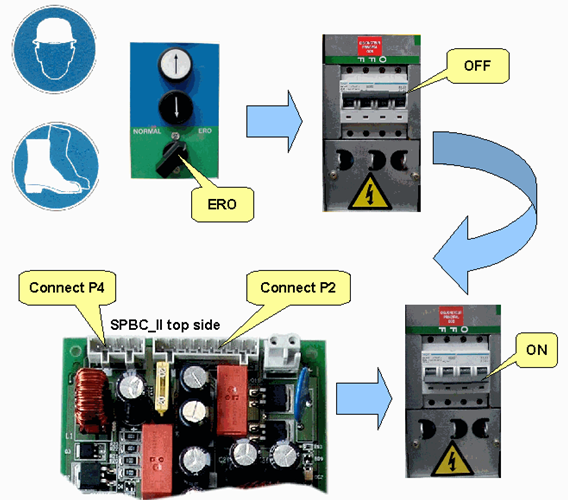

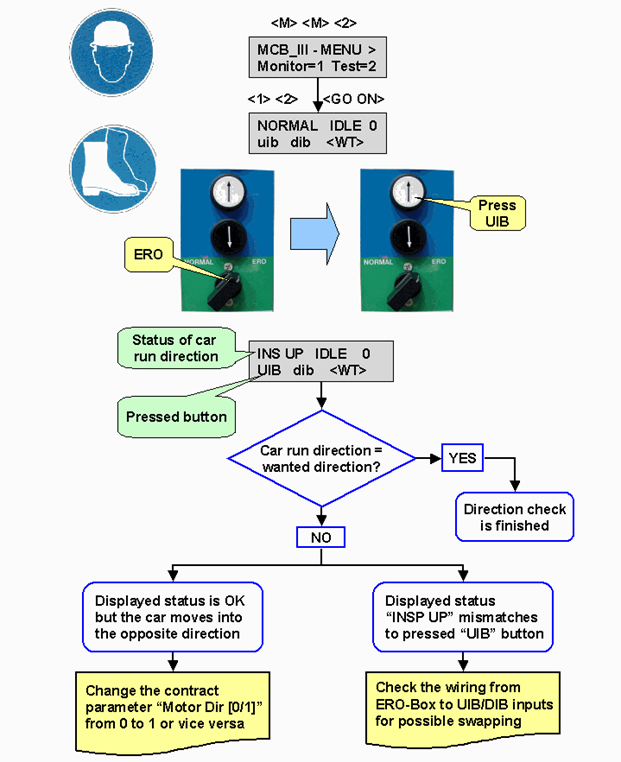

2.3Check Run and Encoder Direction (E/I- panel: SPBC_II)

|

2.4Manual Brake Release check (E/I-panel)

|

3Prepare first Normal Run

| The elevator must be fully completed (wiring and mechanical assembly) before going beyond this point |

3.1Connect P1H and check RS power supply

|

| RSL | Measurement points | RSL Voltage | ||

| Voltage | Reference point | |||

| Car Link (P101C) | P22M:7 | P22M | P22M:8 (HL2) | 27 - 36 VDC |

| Hall Link (P1H) | Terminal 30 | TB2 | P22M:8 (HL2) | 27 - 36 VDC |

3.2Shunt position to NORMAL

|

3.3Parameter Setup (E/I- panel)

|

| Control Parameters | <3> <5> <2> <GOON> | |

| SpC FNr | = | |

| SpC FN0 | = |

| Profile parameters | <3> <2> <GO ON> | |

| INS SPE | = | |

3.4Software verification (self test): E/I- panel

|

3.5Check of hoistway signals (E/I- panel)

|

3.6Start up of DCSS 5

| To startup the DCSS5 please refer to the corresponding Field Service Manual |

3.7Learn run (E/I- panel)

|

3.8DCS – Door Check Sequence (E/I-panel: SPBC_II)

| Note: In case of failure of a hoistway door contact, the car stops on this floor and is locked. An error message is shown. After elimination of all errors, the car has to be moved to the bottom landing first before starting the DCS RUN once again. |

| Attention: The new feature Hoistway Access Detection has been implemented to protect persons who entering the hoistway when they are not properly following the safety instructions. Is the DS contact opened for longer then 2 seconds the TCBC will go into ACC mode, the event “0306HWY Access” is logged. The blinking message “Switch INS” appears in the Status menu. The fault will not be cleared by switching the power off and on, the only way to bring the elevator back into normal operation is by ERO or push-and-pull PES. |

DCS – Door Check Sequence (continued)

|

3.9Load Weighing adjust

| The mechanical and the electrical installation of the LWB_II with load sensors have to be completely finished (CAN wiring, power supply) as described in the FIM |

1.1.1Parameter setup (LWB_II): E/I- panel

|

| No. | Function | value | new calibration necessary? | ||

| min. | max. | default | |||

| full load | 240kg | 3000kg | 1000kg | if changed | |

| total number of pads (rubber pads+ sensors) | if changed | ||||

| number of sensors | if changed | ||||

| ANS | 30kg | 250kg | 100kg | no | |

| LNS | 70% | 95% | 80% | no | |

| OLD | 100% | 110% | 110% | no |

1.1.2Parameter setup (MCB_III): E/I- panel

|

| Contract parameters | <3> <1> <GOON> | |

| LoadW type | = | |

| Start/stop parameters | <3> <4> <GOON> | |

| FULL LOAD [kg] | = | (e.g. 1600) |

| BALANCE [%] | = | (e.g. 47%) |

| ALWcomp Corr [%] | = | (e.g. 100): correction factor to avoid rollback |

1.1.3Offset calibration

|

1.1.4Gain calibration

|

1.1.5Start behavior check

|

4Final Adjustment

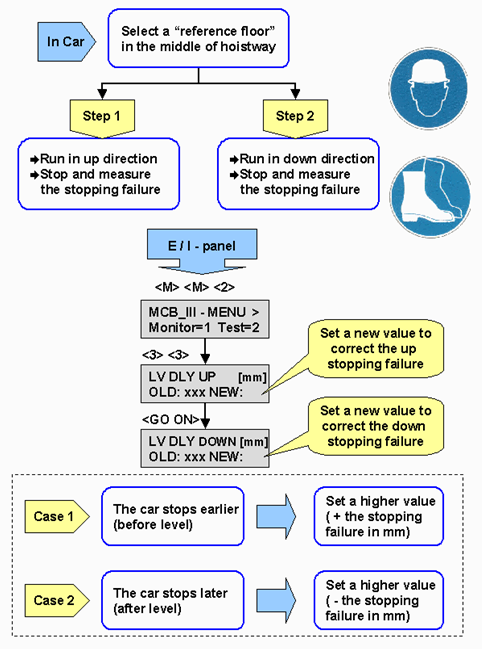

4.1LV delay (up/down) adjustment

|

| Note: If the magnets are adjusted in the same manner at each floor, the car should stop correctly in each landing, otherwise the magnets should be replaced accordingly. Then a new learn run is necessary. |

4.21LS and 2LS delay adjustment

|

4.3Check of ADO and RLV (Option)

|

4.4Parameter storage (MCB_III)

|

| Note: Do not choose the Default-values, otherwise the adjusted contract-specific parameters will be lost. |

4.5Assignment for building configuration

| Note: With the "Allowed Mask", the building configuration (assignment of calls (car / hall), cutting of landings (Cut Call), Card Reader, Parking, Ride profiles) is determined. An assignment is made for every landing. Rear doors are available, if on this landing the elevator may park and with which ride profile the elevator moves to the next landing. The key sequence (M – 1 – 3 – 3) leads to the following "Allowed Menu" |

4.6Position Indicator setup

|

| Code | Symbol | Code | Symbol | Code | Symbol | Code | Symbol |

| (blank) | J (*) | T (*) | |||||

| A | K (*) | U | |||||

| B (*) | L | V (*) | |||||

| C | M (*) | W (*) | |||||

| D (*) | N (*) | X (*) | |||||

| E | O | Y (*) | |||||

| F | P | Z (*) | |||||

| G (*) | Q (*) | - | |||||

| H | R (*) | * | |||||

| I (*) | S | all segments |

(*) for 16-segment position indicator and ELD only!

Appendix

System overview

| Hoistway installation / motor | Controller | Car | Floor | |||||

|

Figure 1: System overview with used control subsystems

Communication network

| Hoistway installation | Controller | Car | Floor | |||

|