In 2005, the photovoltaic market exceeded US$10 billion, showing an exponential annual growth of 30%. Consequently, the shortage of silicon feedstock has forced cell manufacturers to look for new sources. To satisfy the market in the short-term to mid-term, extending feedstock to low-quality materials such as solar-graded silicon or thin film techniques is feasible and has been widely discussed. These approaches require a detailed understanding of not only the carrier transport mechanisms but also process physics, namely, diffusion and gettering processes. With its comprehensive capabilities in device and process simulation, TCAD can provide solar cell engineers with valuable insights to harness the last percentage of cell efficiency.

Weber et al. [1] recently successfully reproduced Fe gettering experiments in boron-doped diffusion processes using Sentaurus Process and Sentaurus Device. In this article, we illustrate the implementation of an aluminum gettering process described by Plekhanov et al. [2].

A crucial material parameter for solar cells to achieve reasonable efficiency is the minority carrier lifetime or diffusion length. A high lifetime is achieved by reducing the number of recombination centers (traps) in the Si wafer.

Therefore, for the successful use of solargraded materials, it is essential to consider defect engineering in the design of the fabrication process. In particular, an optimized design of gettering processes, which reducethe amount and impact of impurities present in the Si wafer, is vital to obtain high cell efficiencies.

Aluminum gettering uses the fact that, above the eutectic temperature of 577∞C, the solubility of metals in Al is very high (1021 cmЦ3) compared to their solubility in Si (1017 cmЦ3). This provides a tremendous driving force for metal atoms to segregate into the Al or AlЦSi liquid layer. As the segregation process occurs simultaneously with the impurity diffusion, the gettering process can be described by:

Ј A segregation equation at the AlЦSi material boundary.

Ј A diffusion equation for the impurity diffusion in bulk silicon.

Ј Reaction terms for cluster dissolution and formation if impurity clusters such as metal precipitates are taken into account in the model.

Basically, for impurity gettering, the same physics can be applied as for dopant diffusion.

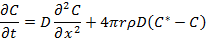

Plekhanov et al. developed a set of equations to describe the gettering of the impurities C, taking into account the decreasing size of metal precipitates C* in silicon:

where D is the diffusivity of the impurity, r is the radius of the metal precipitate, and ρ is the precipitate density.

Sentaurus Process allows users to define new species in silicon and to define new equations for the diffusion, segregation, and reactions of these new species as simple text strings. For example, the following line defines the partial differential diffusion-segregation equation for the impurity Fe in silicon:

pdbSetString Silicon Fe Equation \Уddt(Fe)-$Dm*grad(Fe) PrecDissolФ

|

|

|

For each time step, Sentaurus Process solves this differential equation and provides the spatial distribution of the species.

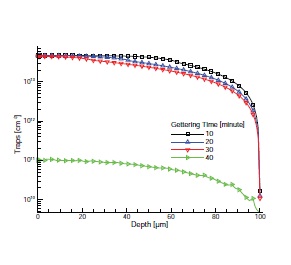

After the reactions and diffusion equations are set up, the process flow with arbitrary temperature ramps can be defined. Here, a 1D simulation with a very simple ramp, namely, a constant temperature at 900∞C for four different gettering times (10, 20, 30, and 40 minutes) is investigated. The rear of the 100-μm thick silicon wafer is covered by Al (at a depth of 100 μm). The main result of the process simulation is the trap distribution shown in Figure 1.

ЂFig. 1їDepth-dependent trap distribution in die silicon wafer for different gettering times.

In addition to the trap distribution, the emitter doping profile can be modeled for use in subsequent device simulations, but this is not discussed further in this article.

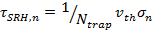

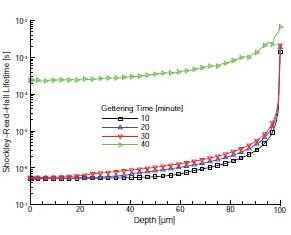

In the next step, the trap distribution passes to the device simulator Sentaurus Device. The trap density Ntrap together with a capture cross section σn translates to a spatially varying ShockleyЦReadЦHall (SRH) lifetime (see Figure 2):

Where ʋth is the thermal carrier velocity.

ЂFig. 2їSpatially varying SRH lifetimes for the device simulation.

To calculate the white-light generation, the transfer matrix method is used. Sentaurus Device offers a variety of different optical solvers such as raytracing, the beampropagation method, and the finite-difference time-domain full-wave Maxwell solver.

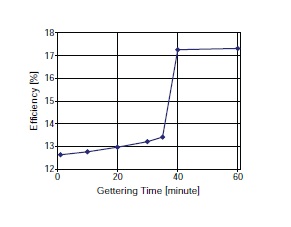

Finally, the influence of process variation on device characteristics is evaluated. Figure 3 shows the influence of gettering

ЂFig. 3їDependency of cell efficiency on gettering time.

time on solar cell efficiency. In this setup, after 40 minutes, all Fe atoms are gettered by the Al rearside, resulting in a strong increase of the shortcircuit current efficiency.

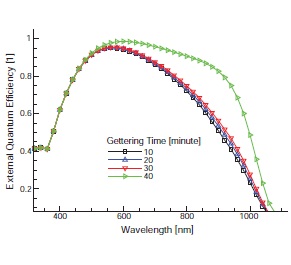

Figure 4 shows the dependency of the gettering time on external quantum efficiency (EQE). Due to a lower minority lifetime, the EQE is lowered in the red part of the spectrum as the carriers generated at the rear are unable to reach the p-n junction.

ЂFig. 4їInfluence of gettering time on EQE.

References

[1] T. Weber et al., УNumerical Simulation of Gettering and Recombination in Iron-Contaminated Boron Emitters,Ф in Proceedings of the 21st European Photovoltaic Solar Energy Conference (EUPVSEC), Dresden, Germany, September 2006.

[2] P. S. Plekhanov et al., УModeling of gettering of precipitated impurities from Si for carrier lifetime improvement in solar cell applications,Ф Journal of Applied Physics, vol. 86, no. 5, pp. 2453Ц2458, 1999.